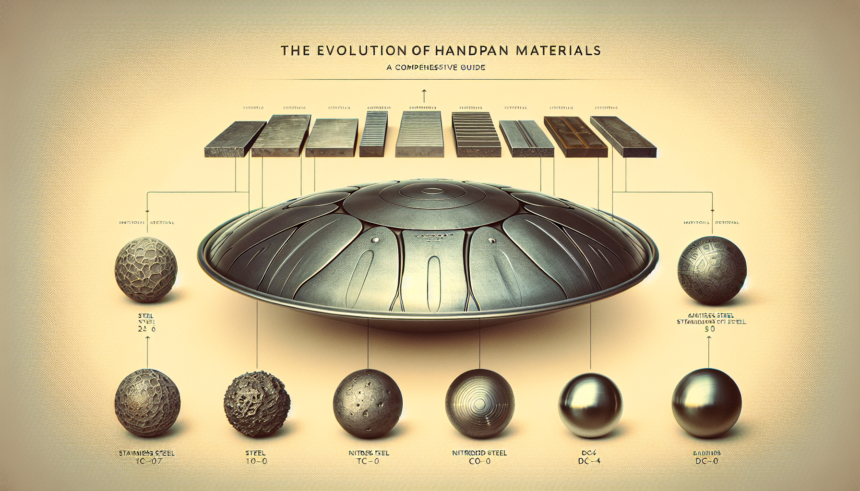

Introduction

The handpan, an evocative melodic percussion instrument, has grown considerably in popularity over the past two decades. Characterized by its ethereal sound and visually striking dome shape, the handpan captures the interest of musicians and enthusiasts alike. One key component in the handpan’s evolution is the material composition, which has notably transformed since its inception. This guide delves into the progression of handpan materials, exploring their impact on the instrument’s sound, durability, and the evolving preferences of handpan makers and players.

Early Material Choices: Steel

The journey of the handpan began in the early 2000s with the creation of the Hang by PANArt. The original Hang was crafted using nitrided steel, which involves a heat treatment process to harden the surface. This method provided a robust yet resonant shell that produced the instrument’s signature mellow and mystical tones.

Steel’s advantages included its availability, workability, and the ability to withstand the high-intensity forging and tuning processes. However, the initial steel handpans were prone to rust and corrosion, necessitating meticulous care and maintenance.

Advancements and Experimentation: Stainless Steel

As the handpan community expanded, makers began to experiment with alternative materials to address the inherent limitations of nitrided steel. Stainless steel emerged as a popular substitute. Unlike traditional steel, stainless steel contains chromium, enhancing its resistance to rust and blemishes.

Stainless steel handpans boast a different timbre from their nitrided counterparts, often described as brighter and more overtone-rich. Additionally, the increased durability of stainless steel handpans made them an attractive choice for musicians who frequently travel or play outdoors. The trade-off, however, was a slightly altered sound profile that didn’t entirely replicate the original handpan tones.

Culture of Customization: Hybrid and Coated Metals

Innovation in the handpan world didn’t stop with stainless steel. Makers began to experiment with hybrid and specially coated metals to achieve a variety of soundscapes and aesthetic qualities. This era marked a culture of customization, where handpan artisans explored various treatments and surface finishes.

Hybrid metals, often combining elements of nitrided steel with stainless steel or other alloys, allowed for versatile sound production. Coated metals, utilizing techniques like PVD (Physical Vapor Deposition) and powder coating, provided additional layers of protection and unique visual appeal. Such advancements rendered handpans more resistant to environmental factors while offering a palette of new sonic possibilities.

The Quest for Perfection: Novel Alloys and Composites

The quest for the ideal handpan material has led makers to investigate novel alloys and composites deliberately designed for musical excellence. These new age materials aim to offer the best of all worlds – the rich resonance of nitrided steel, the durability of stainless steel, and the potential for further enhanced tunability and stability.

For example, some handpan manufacturers have incorporated advanced alloys that fine-tune the instrument’s acoustic properties, providing prolonged sustain and harmonics clarity. Similarly, composite materials, integrating metal with polymer elements, are being explored to reduce weight without compromising on sound quality. These innovations signify the relentless pursuit toward a handpan that is both sonically superior and structurally robust.

Environmental Considerations: Sustainable and Eco-Friendly Materials

In contemporary discussions about handpan materials, sustainability and environmental impact have become significant factors. As with any manufactured product, the choice of materials has implications for resource consumption and waste production. Many modern handpan makers are prioritizing eco-friendly materials and environmentally-conscious manufacturing practices.

Recycled metals and sustainably sourced alloys represent one such approach. By using reclaimed steel and other recyclable materials, producers aim to minimize their environmental footprint. Furthermore, techniques that require less energy-intensive processes, such as cold-forming and plasma nitriding, are being preferred over traditional methods.

These sustainable practices not only appeal to environmentally-conscious consumers but also help preserve the planet for future generations of musicians and listeners.

Conclusion

The evolution of handpan materials is a testament to the instrument’s dynamic nature and the innovative spirit within the handpan community. From the early days of nitrided steel to the modern era of advanced alloys and sustainable practices, the pursuit of the perfect handpan material continues to inspire and challenge makers worldwide.

Each material brings its unique set of characteristics, influencing the sound, feel, and viability of the handpan. This ongoing exploration ensures that the instrument remains a vibrant, evolving form of musical expression, magnifying its appeal and accessibility. Whether you’re a seasoned handpan player or a new enthusiast, understanding the materials behind these magical instruments can deepen your appreciation and enhance your musical journey.

FAQs

1. What is the original material used for handpans?

The original handpan, known as the Hang, was crafted from nitrided steel. This material undergoes a heat treatment process to enhance its hardness and resonant qualities, contributing to the instrument’s distinctive sound.

2. How does stainless steel differ from nitrided steel in terms of sound?

Stainless steel handpans often produce a brighter and more overtone-rich sound compared to nitrided steel handpans, which have a mellower and more mystical tone. The choice between the two depends on the player’s preference and the desired sound characteristics.

3. Why are eco-friendly and sustainable materials becoming important in handpan making?

Eco-friendly and sustainable materials are gaining importance due to the growing awareness of environmental impact. Using recycled metals and eco-conscious manufacturing practices helps reduce resource consumption and waste production, aligning with broader efforts to preserve the planet.

4. What are hybrid and coated metals in handpan manufacturing?

Hybrid metals combine elements of nitrided steel with stainless steel or other alloys to create versatile sound production. Coated metals use techniques like PVD (Physical Vapor Deposition) and powder coating to provide additional layers of protection and unique visual appeal, enhancing both durability and aesthetics.

5. Are there any new materials being used in handpans today?

Yes, novel alloys and composite materials are being developed that aim to offer the rich resonance, durability, and enhanced tunability desired by makers and players. These innovations continue to push the boundaries of what is possible in handpan design and performance.