Shipping a handpan can be a daunting task, given the instrument’s delicate nature and unique shape. Proper packaging is essential to ensure it arrives safely at its destination. This article will guide you through the process of selecting the right packaging materials and methods to ensure your handpan is protected during transit.

Understanding the Importance of Proper Packaging

Handpans are intricate musical instruments with a convex shape that makes them particularly vulnerable to damage. They are typically made from steel and can be sensitive to impact, temperature fluctuations, and pressure changes. Hence, ensuring proper packaging is crucial for preventing dents, scratches, and other damages.

Key Considerations for Shipping Handpans

When preparing to ship a handpan, there are several key factors to consider:

1. Size and Weight

Handpans come in various sizes and weights, and knowing the specific dimensions and mass of your instrument will help you select an appropriately sized box and cushioning materials. A snug fit will minimize movement within the box, reducing the risk of damage.

2. Shipping Distance and Duration

The distance and duration of the shipment can affect the choice of packaging. Longer distances and durations increase the likelihood of the handpan being handled by multiple parties, thus increasing the risk of damage. In such cases, more robust packaging materials may be necessary.

3. Shipping Method

Whether you are using ground, air, or sea freight, each method has its own set of challenges. Ground shipping may involve frequent handling and rough terrain, air shipping can expose the handpan to varying pressure and temperature conditions, and sea shipping may involve prolonged exposure to humidity. Understanding the specifics of the shipping method will help in selecting appropriate protective measures.

Choosing the Right Packaging Materials

There are several essential materials you will need to ensure your handpan is securely packaged:

1. Strong Cardboard Box

Choose a sturdy, double-walled cardboard box that is slightly larger than the handpan. The box should be durable enough to withstand the rigors of shipping. Make sure the box is new or in excellent condition, as previously used boxes may have compromised structural integrity.

2. Cushioning Materials

Proper cushioning is crucial to absorb shocks and vibrations. Suitable materials include:

- Bubble Wrap: Wrap the handpan completely in several layers of bubble wrap to provide a cushion against impacts.

- Foam Pads: Place foam pads at the bottom, sides, and top of the box to create a protective barrier.

- Foam Pellets or Packing Peanuts: These can fill in the spaces between the handpan and the box, preventing any movement.

3. Plastic Bags

Consider placing the bubble-wrapped handpan inside a plastic bag to protect it from moisture. This is especially important if the shipment will be exposed to varying temperature and humidity conditions.

4. Shipping Tape

A high-quality sealing tape will ensure the box stays securely closed. Use at least two layers of tape along all seams and openings.

5. Fragile Labels

Label the box with “Fragile” and “Handle with Care” stickers to alert handlers about the delicate nature of the contents.

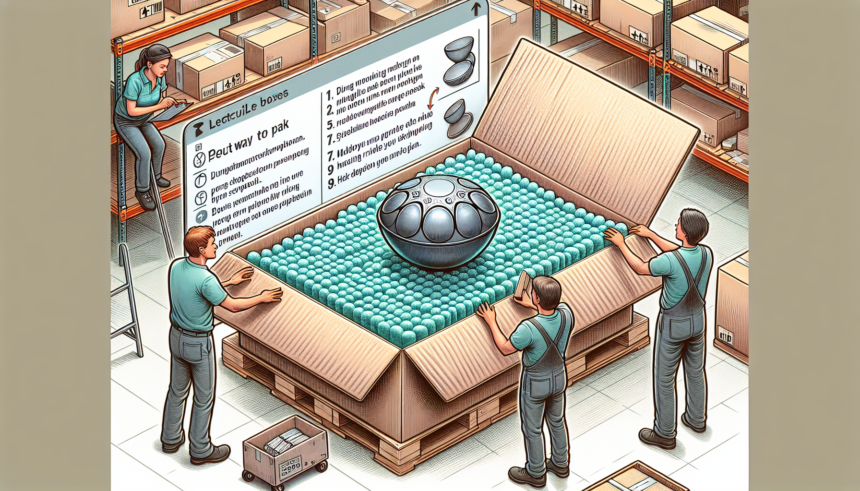

Packaging Process

Follow these steps to ensure your handpan is properly packed for shipping:

Step 1: Measure and Weigh the Handpan

Start by measuring the dimensions and weight of your handpan. This will help in choosing the right size for the box and ensuring it meets shipping requirements.

Step 2: Wrap the Handpan

Wrap the handpan in several layers of bubble wrap, covering all sides. Secure the bubble wrap with tape to keep it in place.

Step 3: Prepare the Box

Place a layer of foam pads at the bottom of the box for cushioning. These pads will act as a shock absorber.

Step 4: Insert the Handpan

Place the wrapped handpan in the center of the box. Ensure it is positioned upright and there is enough space on all sides for additional cushioning.

Step 5: Add More Cushioning

Fill the sides, top, and any gaps around the handpan with foam pads, pellets, or packing peanuts to prevent any movement. Ensure the handpan is securely enclosed.

Step 6: Seal the Box

Close the box and seal all edges with heavy-duty shipping tape. Apply at least two layers of tape along each seam to ensure it is tightly closed.

Step 7: Label the Package

Place “Fragile” and “Handle with Care” labels on all sides of the box to alert handlers. Include a shipping label with your contact information and the destination address.

Conclusion

Shipping a handpan requires careful planning and the right materials to ensure it arrives safely. By considering the size, weight, distance, and shipping method, and by using strong cardboard boxes, cushioning materials, and proper labeling, you can protect your handpan from damage during transit. Following the step-by-step packaging process outlined above will help ensure your instrument reaches its destination in perfect condition.

FAQs

1. What type of box should I use for shipping a handpan?

Use a sturdy, double-walled cardboard box that is slightly larger than your handpan. Ensure the box is in excellent condition to provide adequate protection.

2. How much bubble wrap should I use to wrap my handpan?

Wrap the handpan in several layers of bubble wrap, ensuring all sides are covered. Secure the bubble wrap with tape to keep it in place.

3. Can I use any type of packing peanuts for cushioning?

Foam pellets or packing peanuts can be used to fill gaps and prevent movement within the box. Ensure they are of good quality and provide adequate cushioning.

4. How do I ensure the box stays securely closed?

Use high-quality shipping tape to seal all seams and openings of the box. Apply at least two layers of tape along each seam to prevent the box from opening during transit.

5. Should I label the box with special handling instructions?

Yes, labeling the box with “Fragile” and “Handle with Care” stickers is important. These labels alert handlers about the delicate nature of the contents, encouraging careful handling.